Our components are reliable powerhouses for all agricultural applications – fully certified and electrified, with efficiency and sustainability in mind.

The precise control and regulation of electric drives not only has a positive effect on your agricultural machinery itself, but also on all attached implements. Precisely controllable power, for example, means more accurate sowing, more efficient ploughing and overall better control over all field operations. At the same time, an electric drive reduces dependence on diesel, lowers operating costs and enables sustainable, emission-free operation of your machines. This way, farmers benefit from lower costs and more environmentally friendly technology, while agricultural technology manufacturers can develop innovative, future-proof machines that meet the increasing demands for emission reduction and energy efficiency.

ATECH components for agricultural machinery

ATECH offers a comprehensive range of all the relevant components needed for the electric or hybrid drive of agricultural machinery. Our solutions are characterised by their high adaptability to customer-specific requirements and their excellent efficiency. The following is an overview of the most important components in our portfolio:

- Electric motors: Powerful electric motors with high torque from the first revolution. They are robustly built for rough agricultural use and provide immediate power delivery, which is an advantage when starting up heavy implements in the field, for example.

- Gearbox: Efficient gearboxes, matched to electric drives, ensure optimal power transmission and adaptation of the speed to the respective application. Our gearboxes are durable and low-maintenance – ideal for continuous use in tractors and harvesters

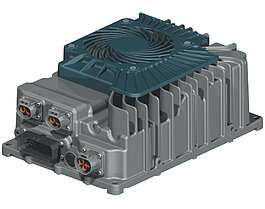

- Power electronics and controllers: Intelligent inverters and control units (controllers) ensure precise control of the motor and efficient energy management. These controllers dynamically adjust the power output to changes in load, thus guaranteeing smooth operation even under changing conditions in the field.

- Flash Battery lithium batteries: With a long service life, enormous flexibility and easy maintenance, Flash Battery lithium batteries are also a convincing solution for agriculture. Thanks to the partial fast-charging function, the batteries also ensure reliable operation.

- Battery chargers (on-board & off-board): high-performance chargers for charging traction batteries both on board the machine and externally. Our chargers are designed for agricultural requirements – they charge batteries quickly, gently and reliably, whether in the barn overnight (on-board) or at the charging station in the yard (off-board).

- Complete drive units: Turnkey, custom-made drive systems that we configure to your specifications. From the combination of motor and gearbox to integrated systems including control and battery – we supply you with complete, tested units that can be seamlessly integrated into your agricultural machine.

Your benefits with ATECH

Hochmoderne Technologie

Our components are equipped with the latest technical innovations and are subject to the highest quality standards. This means that you receive future-proof drive technology that is always at the cutting edge of development.

Zuverlässigkeit

Each component is subjected to rigorous testing to ensure it can withstand even the harshest operating conditions. You benefit from reliable systems with a long service life that minimise downtime and are designed for long-term use in agriculture.

Umweltfreundlichkeit

Switching to electric drive technology significantly reduces emissions. With our sustainable solutions – from energy-efficient motors to environmentally friendly production processes – we actively contribute to protecting the environment and making agriculture greener.

Electric drive technology for agricultural machinery that pays for itself

Modern electric drive technology offers both farmers and manufacturers of agricultural machinery decisive advantages. Farmers benefit from quiet, emission-free machines that increase working comfort – no more engine noise or exhaust fumes in the yard or field. In addition, fuel costs are significantly lower because electricity is cheaper than diesel and can be used more efficiently. Agricultural technology manufacturers can use electric and hybrid drives to implement innovative machine concepts and differentiate themselves in the market through forward-looking technology. Electrical systems also make it easier to integrate automation and precise electronics, which opens up new functions in agriculture.

Fewer emissions, lower costs, maximum efficiency – the future of agricultural technology is electric.

A key advantage of electrically driven agricultural machinery is the drastic reduction of emissions and maintenance costs. Without a combustion engine, exhaust gases are completely eliminated and the consumption of fossil fuels is reduced to a minimum. This not only benefits the environment, but also the health of humans and animals – for example, when tractors are operated in closed halls or stables. At the same time, the elimination of numerous parts that are prone to wear (such as oil filters, exhaust systems or complicated transmission components) significantly reduces maintenance requirements. Fewer moving parts means less wear and higher reliability: your machines are operational for longer and expensive downtime is significantly reduced. The overall simpler technology of an electric drive also enables faster maintenance cycles and lower spare parts costs.

Furthermore, electric drive systems are characterised by a high degree of flexibility and scalability. They can be adapted to a wide range of vehicle sizes and applications – from compact yard loaders to versatile multi-purpose tractors and powerful combine harvesters. Thanks to their modular design, the system's performance can be precisely matched to the respective requirements and easily expanded as demands grow. Hybrid solutions are also possible: for example, electric drives can be combined with existing diesel units to cover peak loads or increase range. This versatility enables customised solutions for every agricultural application. ATECH draws on years of experience in the field of battery-powered electric drives and supports both farmers and machine builders with comprehensive advice – from the initial idea to the final integration. The result is customised drive concepts that perform convincingly in practice and future-proof your business.

ZAPI S.p.A

The leading manufacturer of inverters and accessories for battery-powered electric vehicles.

ZIVAN S.p.A

Manufacturer of battery chargers and charging systems. ZIVAN is a member of the ZAPI Group.

Best Motor S.R.L

Manufacturer of electric drive and hydraulic pump motors. A subsidiary of the ZAPI Group

Inmotion Technologies AB

A ZAPI subsidiary as a global supplier of electric drive motors, controllers and other components

delta-q Technologies

Industrial battery chargers for electric vehicles, golf carts, forklifts, bicycles and motorcycles, cleaning vehicles and much more.

Albright International

The world's leading manufacturer of DC contactors, changeover switches and

emergency stop switches

Anderson Power Products

The leading developer and manufacturer of battery connectors of all types and the matching accessories

Freqcon GmbH

Electronics, converter systems and control technology for wind energy and photovoltaics

Do you have any questions?

Contact us from Monday to Friday, from 8:00 a.m. to 5:00 p.m.

info@atech-antriebstechnik.de or by phone: +49 (86 77) 98 09-0

Experience ATECH drive technology in use

Possible drive solutions for various agricultural

Your contact person for the next project

We can only recommend a personal consultation due to the high level of customisation. Contact your personal point of contact now, without obligation, and they will be happy to answer your questions and discuss your requirements.

Werner Hummel

Leitung TechnikTelefon +49 (86 77) 98 09-14

Telefax +49 (86 77) 98 09-20

werner.hummel@atech-antriebstechnik.de

Frequently asked questions

From tractors and combine harvesters to specialised crop-picking machines, almost any agricultural machine can be equipped with our electric or hybrid drive systems.

Electric drives enable more precise control, lower operating costs, less maintenance and reduced environmental pollution. They also ensure a more pleasant working environment due to lower noise and vibration levels.

Battery life varies depending on the application and load. However, thanks to our optimised systems and energy-efficient control, we achieve a maximum service life that is sufficient for a typical working day. We also offer hybrid systems that provide additional flexibility.

Yes, we offer retrofitting solutions that can be used to convert existing agricultural machinery with combustion engines to electric or hybrid drive systems. This extends the service life of your machines while also reducing operating costs.

Aktuelle News

Hier erfahren Sie alle aktuellen News rund um unsere Produkte und unser Unternehmen. Verpassen Sie kein Event und keine Produktneuheit.