Electric GSE components: Maximum efficiency for your airport logistics

The electrification of ground support equipment is the key to sustainable and economical airport logistics. ATECH Antriebstechnik offers proven solutions for all GSE categories – from baggage tugs and conveyor belt trolleys to heavy aircraft tractors. With our robust IP69K-certified components with up to IP67, you can achieve full performance even at -25°C outside temperatures. Flash Battery lithium technology with over 3,000 charge cycles guarantees minimal downtime, while ZAPI inverters with CANopen interfaces enable seamless integration into existing fleet management systems. The result: up to 60% lower operating costs compared to diesel-powered GSE, 100% emission-free operation and a proven reduction in maintenance intervals by 40%. Benefit from over 35 years of experience in electric mobility and tailor-made retrofit solutions for your existing GSE fleet.

Complete drive solutions for all types of GSE vehicles

As an established system provider for electrical airport ground support equipment, we combine all the necessary technologies under one roof – from drive and control technology to cold-resistant battery systems and automatic charging systems for 24/7 airport operations.

Our GSE component portfolio for your electrification projects

Robust electric motors for continuous operation

High-performance drive motors with up to IP69K protection class for corrosive environments and salt water exposure. Our motors deliver constant torque even at -25°C and are designed for many thousands of hours without failure.

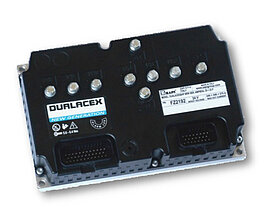

ZAPI inverters with fleet management integration

The proven ZAPI Group inverters (ZAPI / Inmotion) in AC and PMAC/PMSM technology and BLE series enable CAN bus connection to airport management systems and offer integrated diagnostic functions. Safety certification according to ISO 13849-1 for critical GSE applications.

Flash Battery lithium systems for extreme conditions

Cold-resistant lithium iron phosphate batteries with integrated heating management for winter operation. Fast charging option: 80% capacity in 45 minutes for minimal downtime between shifts. 50% capacity in 30 minutes.

The ATECH advantages for your GSE electrification

Proven airport expertise

Over 30 years of experience in the electrification of GSE fleets. Our components are used in critical airport environments worldwide and meet the highest availability standards.

retrofit specialist

Electrification of existing GSE without purchasing new vehicles. Our modular systems enable cost-efficient retrofitting of legacy equipment with payback periods of less than 18 months.

Extreme environmental suitability

IP69K certification, saltwater corrosion protection and operating temperatures from -25°C to +60°C. Designed for the harshest conditions of the airport environment.

Customised GSE solutions for every airport area

ATECH understands the specific requirements of different GSE categories. For baggage tractors, we offer compact drive units with regenerative braking and optimised turning circle performance. Pushback tractors benefit from our high-torque systems with up to 15,000 Nm for heavy commercial aircraft. Conveyor belt trolleys and catering trucks are equipped with precise hydraulic pump controls for smooth workflows. The modular ZAPI architecture enables standardised spare parts management for the entire fleet, while Flash Battery BMS remote monitoring enables predictive maintenance and fleet optimisation in real time.

Your partnership with ATECH – from concept to turnkey solution

We support you from the initial GSE electrification strategy to complete fleet implementation. Our engineers analyse your existing vehicles and develop cost-optimised retrofit concepts that can be implemented without interrupting operations. We use proven components such as temperature-stable ZIVAN chargers, EPS-BLI steering controls for tight turning manoeuvres and modular Best Motor hydraulic systems. Standardised CAN interfaces guarantee seamless integration into Airport Collaborative Decision Making (A-CDM) systems. For large-scale projects, we offer pilot vehicle programmes and step-by-step fleet conversions with leasing options. With our Europe-wide service network and 24/7 support, we ensure the continuous availability of your electrified GSE fleet. Benefit from our expertise and reduce your GSE operating costs by up to 60% – as already achieved in reference projects at major European airports.

ZAPI S.p.A

Der führende Hersteller von Invertern und Zubehör im Bereich der batteriebetriebenen Elektrofahrzeuge.

ZIVAN S.p.A

Hersteller von Batterieladegeräten und -ladesystemen. ZIVAN ist ein Unternehmen der ZAPI-Gruppe.

Best Motor S.R.L

Hersteller von elektrischen Antriebs- und Hydraulikpumpen-Motoren. Ein Tochterunternehmen der ZAPI-Gruppe

Inmotion Technologies AB

Eine ZAPI-Tochter als weltweiter Anbieter elektrischer Antriebsmotore, von Controllern und weiteren Bauteilen

delta-q Technologies

Industrielle Batterieladegeräte für elektrische Fahrzeuge, Golf-Fahrzeuge, Stapler, Fahr- und Motorräder, Reinigungsfahrzeuge u.v.m.

Albright International

Der weltweit führende Hersteller von Gleichstrom-Schützen, -Wechslern und

Notaus-Schaltern

Anderson Power Products

Der führende Entwickler und Produzent von Batteriesteckern aller Art und dazu passendem Zubehör

PMP Industries

Ein weltweit vertretender Hersteller von Getrieben für Fahrzeugantriebe und Windkraftanlagen

Do you have any questions?

Contact us Monday to Friday, from 8 a.m. to 5 p.m. Email: info@atech-antriebstechnik.de or by phone: +49 (86 77) 98 09-0

Directions/Contact

Experience ATECH drive technology in action

Possible drive solutions for various agricultural machines

Your contact person for the next project

We can only recommend a personal consultation due to the high level of customisation. Contact your personal point of contact now, without obligation, and they will be happy to answer your questions and discuss your requirements.

Werner Hummel

Leitung TechnikTelefon +49 (86 77) 98 09-14

Telefax +49 (86 77) 98 09-20

werner.hummel@atech-antriebstechnik.de

Frequently asked questions

Electric GSE systems reduce operating costs by 40-60% compared to diesel vehicles. The main savings come from lower energy costs (electricity vs. diesel), reduced maintenance intervals and longer component life. Typical ROI times are between 12-18 months.

Yes, our Flash Battery systems are designed for temperatures ranging from -25°C to +60°C. The integrated thermal management system preheats the batteries in cold weather and cools them in hot weather, ensuring full performance all year round.

ATECH specialises in retrofit solutions for existing GSE fleets. Vehicles that are 10 years old or older can usually be electrified cost-effectively. A case-by-case assessment determines the technical feasibility and economic viability.

Depending on the size of your fleet, we recommend a combination of fast-charging hubs (for shift changes) and slow overnight charging stations. Our planning experts will design the optimal charging infrastructure based on your operating hours and vehicle rotations.

Aktuelle News

Hier erfahren Sie alle aktuellen News rund um unsere Produkte und unser Unternehmen. Verpassen Sie kein Event und keine Produktneuheit.