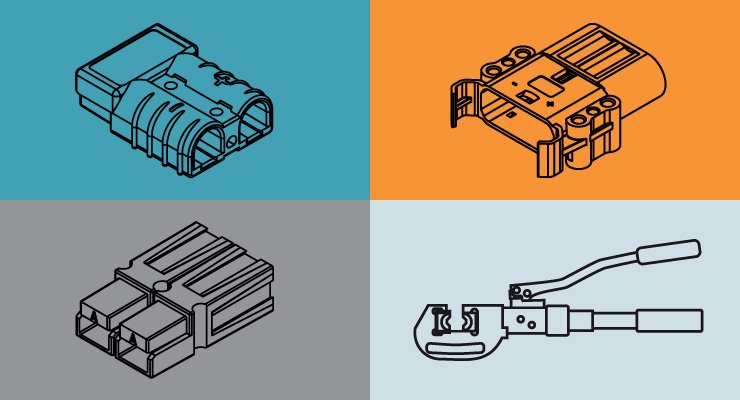

Battery connector between battery and vehicle

General information

The plug for battery operation may be one of the most straightforward inventions in the field of electric vehicles, but it is a vital component and can - if not carefully selected - be a constant source of error for apparatus, circuits and batteries.

For 100 years, Anderson Power has distinguished itself with the highest level of expertise in the field of power components among battery-powered connectors, and is known worldwide for its quality. Especially in the field of "SB" and "SBX" connectors, which are considered the industry benchmark for battery operation, the highest level of customer satisfaction is registered.

The success is based on the following typical characteristics:

1. Quality

The contacts are manufactured according to Anderson's patented "self-cleaning" principle and guarantee insensitivity to vibration and sparking through constant pressure of the leaf springs, thus protecting the battery and technical equipment.

Silver plated copper contacts ensure higher conductivity and longer life with above average use. Low contact resistance also permits short-term overload.

The contacts can be either crimped or soldered to the supply line. The identical housing halves are made of the durable, electrically strong Lexan polycarbonate and include the completely stainless steel leaf springs. High resistance and long life are guaranteed by the mentioned material and a simple but mechanically stable construction. The connectors are tested for 15,000 mating operations.

2. Economy

Stock-keeping is simplified by completely identical connector halves. Each connector half consists of only 3 parts: a housing and two identical contacts. Installation is time and labour saving and reduces assembly costs. Operating costs are also reduced due to the stable construction and durable contacts.

3. Safety

The housings are made of non-conductive material and make plug connections with reversed polarity impossible. The contacts can be replaced independently of each other for greater safety for personnel and equipment.

The halves of the housing, which are mechanically coded, are also colour coded to prevent possible dangerous and costly mismatching between batteries and systems or chargers of different voltages.