FTF & AGV drive technology: Maximum efficiency for your intralogistics

The electrification of driverless transport systems is the key to economical and sustainable intralogistics. ATECH Antriebstechnik offers you proven solutions that are already in use by global market leaders. With our drive units, you can achieve payloads of up to 6,000 kg per wheel, while Flash Battery technology guarantees maximum availability with 50% charge in just 25 minutes. Our ZAPI Group inverters with standardised CAN interfaces enable seamless integration into existing automation systems. The result: up to 40% lower operating costs, 100% emission-free operation and a proven 35% increase in efficiency in material flow optimisation. Benefit from over 35 years of experience in electric mobility and tailor-made solutions for your industry.

Electric drive solutions for driverless transport systems

Modern FTF and AGV require high-precision, reliable and energy-efficient drive components. As a system provider, ATECH combines all the necessary technologies under one roof – from drive and control technology to energy supply systems and safety solutions.

Our component portfolio for your AGV & AGV applications

ATECH Antriebstechnik offers you a perfectly coordinated range of electrical components that have been specially developed for the requirements of modern AGVs and AGVs. Our portfolio includes all the necessary components for the successful electrification of your driverless transport systems.

Our drive solutions from the ZAPI Group

Our drive solutions from the ZAPI Group offer a load capacity of up to 800 kg per wheel and combine motor, gearbox and control in a compact unit. The integrated braking torque control of 1-3 Nm guarantees precise manoeuvring and a secure hold.

Intelligent control technology with CAN interfaces

ZAPI Group inverters (ZAPI/Inmotion) enable seamless integration into existing automation environments via CANopen, and also via additional interface interfaces such as EtherCAT or PROFINET. With safety functions in accordance with EN13849, they meet the highest safety standards.

High-performance battery systems for continuous operation

Flash Battery lithium technology with over 3,000 charging cycles and integrated BMS guarantees maximum availability. The fast charging function achieves 50% capacity in just 25 minutes.

The ATECH advantages for your FTF & AGV projects

Technological leadership

30 years of experience in electric mobility combined with state-of-the-art technology. Our components set standards in efficiency and reliability – confirmed by reference projects with global market leaders.

Economic Efficiency

Reduce your total cost of ownership by up to 40%. Our low-maintenance systems pay for themselves in less than 24 months and have been proven to increase logistics efficiency.

Sustainability

100% emission-free, noise levels below 65 dB and efficiency ratings above 95%. Our drive solutions meet the highest environmental standards and improve working conditions.

Customised drive solutions for your industry

ATECH understands the specific requirements of different industries. In automotive production, our eWheel systems enable millimetre-precise navigation between assembly lines with tolerances of less than 2 mm. Pharmaceutical warehouses benefit from the cleanroom suitability and whisper-quiet operation of our drives. The modular system architecture allows flexible adaptation to your individual needs – from compact shuttle systems with a payload of 100 kg to heavy AGVs with a transport capacity of over 5 tonnes.

Your partnership with ATECH – From idea to implementation

We accompany you every step of the way to the optimal AGV solution. Our experts analyse your existing processes and work with you to develop the ideal drive concept. We use proven components such as ZAPI inverter technology, EPS-BLI steering controls and ZIVAN charging systems. Standardised interfaces guarantee smooth integration into your WMS and MES systems. We also offer tailor-made solutions for retrofit projects, which has enabled us to successfully modernise existing fleets. With our comprehensive documentation, training and Germany-wide service network, we ensure the long-term success of your investment. Benefit from our expertise and increase your intralogistics efficiency by up to 35%.

ZAPI S.p.A

Der führende Hersteller von Invertern und Zubehör im Bereich der batteriebetriebenen Elektrofahrzeuge.

ZIVAN S.p.A

Hersteller von Batterieladegeräten und -ladesystemen. ZIVAN ist ein Unternehmen der ZAPI-Gruppe.

Best Motor S.R.L

Hersteller von elektrischen Antriebs- und Hydraulikpumpen-Motoren. Ein Tochterunternehmen der ZAPI-Gruppe

Inmotion Technologies AB

Eine ZAPI-Tochter als weltweiter Anbieter elektrischer Antriebsmotore, von Controllern und weiteren Bauteilen

delta-q Technologies

Industrielle Batterieladegeräte für elektrische Fahrzeuge, Golf-Fahrzeuge, Stapler, Fahr- und Motorräder, Reinigungsfahrzeuge u.v.m.

Albright International

Der weltweit führende Hersteller von Gleichstrom-Schützen, -Wechslern und

Notaus-Schaltern

Anderson Power Products

Der führende Entwickler und Produzent von Batteriesteckern aller Art und dazu passendem Zubehör

PMP Industries

Ein weltweit vertretender Hersteller von Getrieben für Fahrzeugantriebe und Windkraftanlagen

Do you have any questions?

Contact us Monday to Friday, from 8 a.m. to 5 p.m. Email: info@atech-antriebstechnik.de or by phone: +49 (86 77) 98 09-0

Directions/Contact

Experience ATECH drive technology in action

Possible drive solutions for various agricultural machines

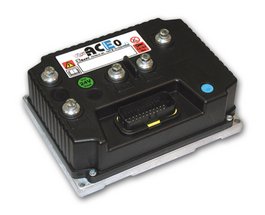

ACE-X NG / BLE-X NG

Abmessungen: 150 x 120 x 65 mm

Eingangsspannung: 24 – 80 V

max. Strom: 40 – 240 A

ACE-1 NG / BLE-1 NG

Abmessungen: 150 x 200 x 77 mm

Eingangsspannung: 24 – 80 V

max. Strom: 125 –400 A

Your contact person for the next project

We can only recommend a personal consultation due to the high level of customisation. Contact your personal point of contact now, without obligation, and they will be happy to answer your questions and discuss your requirements.

Werner Hummel

Leitung TechnikTelefon +49 (86 77) 98 09-14

Telefax +49 (86 77) 98 09-20

werner.hummel@atech-antriebstechnik.de

Frequently asked questions

B-Drives' eWheel systems offer up to 800 kg load capacity per wheel, integrated braking torque control (1-3 Nm) and enable cornering with minimal space requirements. Efficiency of over 95% reduces energy costs by up to 30% compared to conventional drives.

Flash Battery systems reach 50% charge in just 25 minutes and 100% in under 90 minutes. The partial fast-charging function enables "opportunity charging" during short downtimes, allowing for virtually uninterrupted 24/7 operation.

Yes, our modular components are ideal for retrofit projects. The ACH3 inverters with standardised CAN interfaces can be integrated into existing control architectures. We have already successfully modernised fleets belonging to the E80 Group.

Our systems are certified according to EN ISO 13849-1 and EN 1175-1 and achieve Performance Level d (PLd) and SIL2. The integrated safety functions were developed specifically for personal protection in intralogistics and comply with all relevant EU directives.

Aktuelle News

Hier erfahren Sie alle aktuellen News rund um unsere Produkte und unser Unternehmen. Verpassen Sie kein Event und keine Produktneuheit.