The miracle work lithium - the power source for long-lasting batteries

Lithium batteries are already the measure of all things in many areas of application. And yet we have redefined the limits of battery technology through intensive research. Are you a manufacturer of industrial machinery or electric vehicles looking to switch from lead to lithium to improve charging times and energy efficiency?

Our battery technology offers higher performance than any other battery type and has been perfected for use in industrial machinery as well as electric vehicles. A 20 times faster balancing speed, a 50% charge in under 30 minutes, efficient remote maintenance technology - these are all features of Flash Battery lithium batteries. But what exactly is in store behind the technology? What are the benefits for you as a user?

In this article, we'll delve a little deeper and show you where the clear differences between lead-acid batteries, conventional lithium batteries and our Flash Battery lithium batteries can be identified.

Who/what is behind Flash Battery

Flash Battery Srl was founded in 2012 by Marco Righi and Alan Pastorelli, CEO respectively Technical Director.

Flash Battery designs lithium batteries with excellent performance for manufacturers of industrial machinery and electric vehicles with medium production volume and high customization requirements. Maintenance costs are largely eliminated and batteries are charged quickly.

Anton Eberharter, General Manager Atech GmbH:

„For Atech, the cooperation agreement with Flash Battery means first and foremost to rely on the best quality and highly customized products that perfectly integrate with the products we represent in the market today. We will be able to respond to the electrification of our customers, to implement requirements in an effective way, and to deliver complex powertrain solutions.“

Marco Righi, CEO von Flash Battery:

“Atech is the partner of excellence to strengthen our presence in very demanding markets, where an in-depth knowledge of the sector is required for project development, including at the prototype level.“

30 years of experience

ATECH offers you over 30 years of experience in the electrification of industrial vehicles, construction machinery, agricultural machinery, AGVs and many other mobile applications.

Your competent partner

ATECH supports you from the idea, planning, prototype phase to series delivery.

Everything from one source

We support you in the complete dimensioning of your powertrain solution.

Reduced weight

5 times lighter than a lead-acid battery. Flash Battery's lithium battery weighs only 6 kg per kWh (compared to 30 kg per kWh for lead-acid batteries).

Fast charging function

Charging 50% in 25 minutes. Flash battery allows partial charging. Fast charging increases battery life as well as available energy.

Zero maintenance

No routine maintenance required. No need for a separate loading room, vapor extraction system, or demineralizer. All of these costs are avoided.

Remote maintenance

Each work cycle is monitored and controlled, drastically reducing machine downtime.

Long lasting

Over 4000 battery life cycles. Flash Battery lithium battery lasts four times longer than a conventional lead-acid battery.

Balancing system Flash Battery

Flash Battery offers you a balancing system 20 times better than other lithium battery manufacturers. The high performance active and passive flash balancing system balances battery power volume and eliminates maintenance.

Lead batteries and conventional lithium batteries in comparison

Lead batteries

- Long charging times or battery replacement required

- Comparatively short service life (approx. 1000 charging cycles)

- Low energy efficiency (75%)

- High maintenance and infrastructure costs

- Narrow operating temperature range

- Partial charging and discharging shortens service life

Lithium batteries

+ Short charging times - in some cases complete charging in only 2 hours.

+ Long service life (approx. 4000 charging cycles)

+ High energy efficiency (96%)

+ No maintenance and infrastructure costs

+ Wide operating temperature range

+ Partial charging and discharging extend service life

Conventional lithium batteries and Flash Battery lithium batteries compared

Conventional lithium batteries

- Only passive balancing with low power

- Charging up to 50% in 60 minutes

- Long balancing time of 4-8 hours

- High risk of sudden machine downtime

- Standard batteries

FlashBattery lithium batteries

+ Active and passive balancing with a 20 times higher power.

+ Charging up to 50% in 25 minutes

+ Short balancing time in less than 30 minutes

+ No risk of sudden machine breakdowns due to daily remote analysis

+ Customized batteries with individual design

Lithium - An element that provides power

Lithium is characterized by extreme lightness, as it is the lightest metal in nature and also the solid with the lowest density and the greatest electrochemical potential. These properties provide excellent energy performance despite its light weight.

No wonder lithium is the ultimate in battery development. Depending on the chemistry composition used, a typical lithium-ion battery produces 2.4 to 3.7 volts per element.

A short excursion into science - the chemistry is simply right here!

After intensive research, we have chosen Li-Fe-PO4 chemistry for our lithium batteries, which is currently the safest and most stable composition for batteries on the market. This composition allows a much longer lifespan with more than 4000 charging cycles.

Another advantage using this composition is that it can also be provided for large capacity formats (100, 200, 300 Ah), which are particularly relevant for industrial applications. Therefore, a parallel connection of many individual small cells is no longer necessary and the stability and safety of the batteries is not put at risk.

Intelligent charge control ensures a long life cycle

The cells of a lithium battery have different capacities, resistances and self-discharges, which is why there are slight differences in the charging processes, especially when charging several batteries. In practice, this means that one cell is fully charged, while another cell is only 95% charged.

At first glance, the difference may hardly be noticeable. However, with each additional charge cycle, this difference adds up and eventually leads to a high discrepancy, which in the worst case can result in severe damage and malfunctions, both to the battery and to the vehicle or machine.

To avoid this loss of efficiency, the internal electronics of the Flash Battery lithium battery intelligently balance the charge levels in the cells during a charge or discharge process.

Conventional balancing systems lower the charge level to match the lowest cell by applying resistance to the cells with the largest charge. In principle, this method is quite simple and inexpensive, but it takes a relatively long time: four to eight hours are needed on average for balancing alone, in addition to the initial charging process. Moreover, these processes for balancing must not be interrupted, otherwise the available energy will be reduced and vehicles as well as machines will lose operating time.

How did we solve this problem? By using a special active and passive balancing process already during the charging cycles, we ensure that the charges are balanced 20 times faster, thus guaranteeing maximum operating time at all times.

The advantages at a glance:

Combined charge balancing

(active/passive)

Short charging times

from less than 30 minutes

Active support

of the weaker battery cells during discharge

Total control

with 50 temperature sensors on an 80V battery

A maintenance-free technology saves time and costs

By using special control electronics inside our lithium batteries, regular maintenance work is no longer necessary, which subsequently leads to enormous savings.

The core of the whole concept lies in the interaction between the internal architecture of the battery, the combined charge balancing and the extensive analysis and remote monitoring capabilities. Repairs can thus be carried out directly at the user's site by non-specialized personnel, eliminating complicated transport costs and long downtimes.

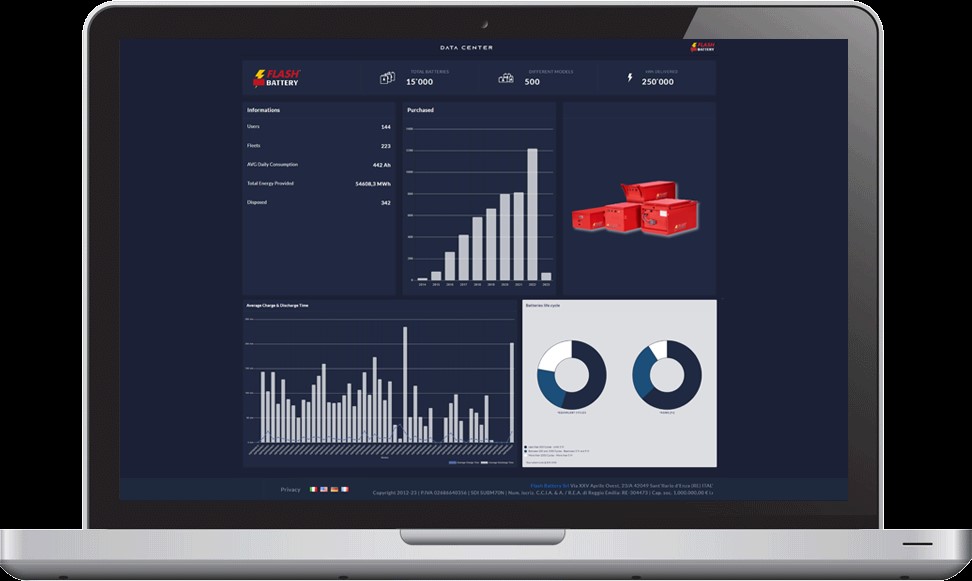

Important parameters always in view - The Flash Data Center for efficient remote monitoring

The remote monitoring system (Flash Data Center) is the mind behind the lithium batteries. On a daily basis it reports any faults that may arise and determines the status of each individual battery at all times. This is how you protect your batteries from unwanted misuse or technical anomalies.

The software is designed to also detect and eliminate false signals. This prevents errors in general, before you as a user even notice it.

The Flash Data Center offers:

- a monitoring of all parameters for each individual battery

- a comprehensive analysis of all usage data for the optimization of your machines and vehicles

- notification of malfunctions

- continuous, automated fault prevention

- organization options for extraordinary repairs

- enormous savings in maintenance costs

- increased productivity of machines and vehicles

Safety comes above all

Safety is one of the multiple strengths of our lithium batteries. We use only the safest chemistry available on the market. Even in the event of a short circuit, it remains intact. How does that work?

FlashBattery lithium batteries are equipped with safety valves which, in the event of an anomaly, releases only internal electrolytes to avoid exceeding the 80°C temperature.

Adaptability says it all

Our lithium batteries are equipped with their own heating and cooling systems to ensure safe and powerful operation at temperatures ranging from -30°C to +45°C. This way, the batteries remain powerful and adapt perfectly to different application areas - for example, cooling systems in the industrial sector.

Branches that benefit from the use of lithium batteries:

Agricultural machines

The European agricultural sector is showing a strong trend towards electrification, especially in areas such as viticulture, zootechnics and the conservation of green spaces. In viticulture, it is now possible to perform all land preparation work from brush cleaning to surfacing with all-electric machines. All-electric harvesters offer the same performance as heat machines, but also all the benefits of electricity: no maintenance and associated costs, CO2 emissions and lower noise levels. In zootechnics, automotive feed mixers (machines for mixing feed for animals, present in the most avant-garde farms and attentive to animal welfare) represent a new electric solution. Most of these applications involve high-voltage batteries, these require a great deal of mechanical adaptation. Flash Battery makes battery customization in terms of size and power its true strength. To date, the company produces more than 550 different models. In many cities, green space conservation is shifting to hybrid or all-electric systems. This trend is particularly evident in wood chippers, which benefit from the advantages of lithium in terms of emissions and noise suppression.

AGV and LGV vehicles

Automatically guided (AGV) and laser guided (LGV) vehicles

FTFs and LGVs are advanced technological systems that move autonomously, reducing lead times, costs and errors within the automated system of a logistics warehouse or production facility. Flash Battery lithium batteries in FTFs and LGVs improve system efficiency even with intensive use around the clock. All maintenance costs are eliminated and the remote battery condition monitoring system automatically performs self-diagnosis and preventive maintenance.

Special vehicles

The special equipment used in construction, maintenance of the railroad network or even tunnels, are industrial machines that require high power. Energy consumption should not be forgotten in the electrification of these applications. These sectors are extremely energy-intensive and therefore it is essential to give the machine enough autonomy and power if it is to be electrified. With lithium batteries from Flash Battery, all this is possible thanks to the increased energy density, which provides even more energy and power in a smaller volume and maintains the high level of safety that we guarantee worldwide. The 4G, with which this particular equipment is supplied, allows for preventive remote control. Data on battery operation and machine use are evaluated daily and automatically. The remote control plays a crucial role already during the design and pre-production phases: it allows the remote control of the actual consumption of the machine during the test phases and the first use in the field. The remote control also allows us to determine the actual charging and discharging times, the days of use, the average consumption and the temperatures reached, thereby optimizing the performance of the battery and the machine.